Introduction

In industrial environments where efficiency, precision, and reliability are non-negotiable, the technology behind air movement plays a crucial role. Among the most common and reliable technologies used for forced air movement is the forward bladed centrifugal blower. These blowers are indispensable in a wide range of industries — from HVAC systems and material handling to combustion air supply and ventilation in heavy machinery.

This article explores the inner workings, design advantages, performance characteristics, and application use cases of forward bladed centrifugal blowers, helping engineers and plant managers understand why this specific blower type continues to be a go-to solution in industrial air systems.

What Is a Forward Bladed Centrifugal Blower?

A forward bladed centrifugal blower (also referred to as a forward-curved blower) is a mechanical device designed to move air or gas through a system using centrifugal force. The key characteristic of this blower is its impeller blades, which are curved in the direction of the rotation.

When the impeller spins, air is drawn into the center (inlet) and propelled outward through the blades. The forward curve of the blades increases air velocity and pressure, directing it toward the blower’s outlet.

These blowers are known for delivering high-volume, low-to-medium pressure airflow — a feature that makes them especially valuable in large-scale ventilation and air handling systems.

How Forward Bladed Blowers Work: The Technical Mechanics

The operating principle is based on centrifugal acceleration. As the motor drives the impeller, the air or gas enters through the center axis. The impeller blades, with their forward curve, catch the air and throw it outward, using the kinetic energy generated by rotation.

The forward-curved blade design increases the surface contact with the air, which translates into higher flow rates at lower speeds. Compared to backward-inclined or radial blades, forward-curved designs offer more blades per impeller, resulting in quieter operation and greater static pressure at lower rotational speeds.

This design, however, also means they are more sensitive to changes in static pressure and can suffer from lower efficiency in high-pressure environments — a trade-off often acceptable in HVAC and light industrial applications.

Design Features and Benefits

Compact Build

Forward bladed centrifugal blowers typically have a compact housing, making them ideal for installations where space is limited. Their ability to deliver high airflow in a small footprint is crucial for OEM systems and packaged HVAC units.

High Flow at Low RPM

One of the main advantages is the ability to produce high volumetric flow at relatively low rotational speeds, reducing wear and extending motor life. This characteristic also contributes to noise reduction.

Energy-Efficient at Design Point

When operated close to their design point, these blowers are energy-efficient, although performance may decline if they are consistently used outside their optimal range.

Noise Reduction

Because they operate at lower RPMs and have more blades engaging the air stream, forward-curved blowers tend to be quieter than backward-curved or radial types. This makes them suitable for indoor environments or machinery located near workspaces.

Limitations and Engineering Considerations

While they offer multiple benefits, forward bladed centrifugal blowers also have limitations that engineers must account for during system design:

- Efficiency drops at high static pressures.

- More prone to dust accumulation on blades due to tight spacing.

- Must be operated near the best efficiency point (BEP) to avoid overloading the motor.

- Cannot handle highly contaminated or corrosive gases unless specially designed.

To mitigate these drawbacks, careful selection of materials, incorporation of filters, and routine maintenance are recommended.

Applications in Industrial Settings

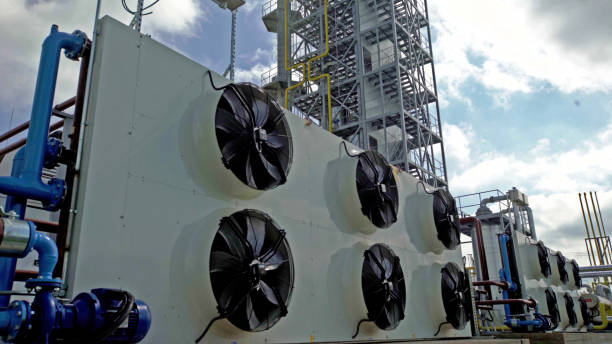

Forward bladed centrifugal blowers are used in a wide array of industrial systems where airflow volume is more critical than pressure. Common applications include:

- HVAC systems in manufacturing plants, data centers, and commercial buildings

- Combustion air supply for industrial burners and boilers

- Cooling electronic enclosures, motors, and drive cabinets

- Dust collection systems with moderate particulate load

- Paint booths, spray dryers, and other controlled environments requiring clean air

- Food processing facilities where quiet operation is essential

In all these settings, the blower ensures a steady, reliable flow of air, crucial for maintaining temperature, air quality, or process consistency.

Material and Build Considerations

The choice of materials for the blower housing and impeller depends heavily on the operating environment:

- Galvanized steel is commonly used for standard applications.

- Aluminum offers a lightweight, corrosion-resistant option.

- Stainless steel is preferred for humid or corrosive environments, such as in chemical or food processing plants.

- Plastic or composite impellers are used in specialized low-load environments.

Seals, bearings, and motor types should be selected based on the expected temperature ranges, humidity levels, and airborne contaminants.

Comparing Forward Bladed to Backward and Radial Blowers

Understanding the difference between blower types helps ensure you select the optimal one for your system. Here’s how forward-curved models stack up:

- Forward vs. Backward Curved: Forward delivers higher volume at lower pressure and is quieter. Backward is more efficient at high pressure but noisier.

- Forward vs. Radial Blade: Radial fans handle high pressure and dirty air better but are louder and less efficient.

Choosing the right blower depends on your system’s pressure requirements, spatial constraints, noise limits, and air quality concerns.

Integration with Modern Control Systems

In today’s Industry 4.0 environments, forward bladed centrifugal blowers are increasingly integrated with variable frequency drives (VFDs), PLCs, and smart monitoring systems. This enables:

- Dynamic adjustment of blower speed based on demand

- Energy consumption monitoring

- Predictive maintenance via vibration and temperature sensors

These features not only optimize blower performance but also contribute to plant-wide energy efficiency and downtime reduction.

Maintenance Best Practices

To maintain performance and extend the life of a forward bladed centrifugal blower:

- Schedule regular cleaning of impellers to prevent buildup

- Check and replace motor bearings and seals periodically

- Monitor vibration and noise levels for signs of imbalance or wear

- Ensure that the blower operates within the recommended pressure curve

Preventive maintenance is crucial, especially in continuous-duty applications where even a brief blower failure can lead to significant downtime.

Conclusion

Forward bladed centrifugal blowers represent a time-tested, cost-effective solution for industries requiring high airflow at moderate pressures. Their quiet operation, compact design, and compatibility with modern control systems make them an essential component in a variety of industrial air handling applications.

When selected and maintained correctly, these blowers deliver consistent performance and can be tailored to meet specific operational challenges — from cleanroom air circulation to thermal management in heavy equipment.

For industrial decision-makers, understanding the nuances of blower design is more than a technical detail; it’s a strategic factor in achieving operational excellence.

If you’re designing or upgrading an air movement system, don’t overlook the value of a forward-curved centrifugal blower. It might just be the quiet, efficient powerhouse your system needs.